Improving PID loop performance – important, yet often forgotten

by Sam Dhaliwal

There are many thousands of PID loops on a typical operating facility such as a refinery, chemical or petrochemical plant. PID loops set the basic stability criteria for operating plants and are the building blocks for further optimisation, yet they are often forgotten and not maintained. Why are PID loops important? How do you ensure that there is continuous focus on maintain good PID loop performance?

PID loops are the building blocks of automatic control

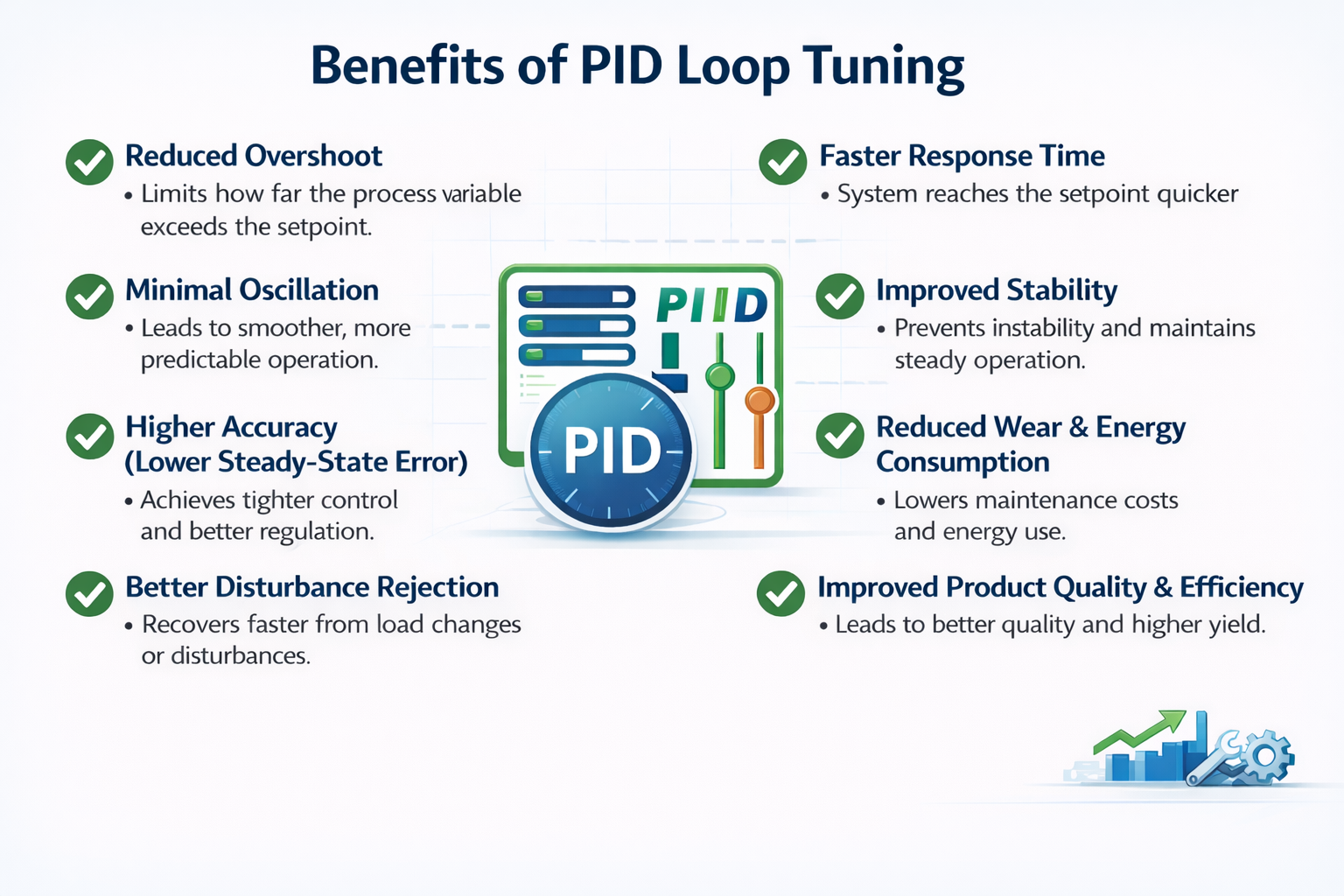

Whether it is control of reactor temperature or feed flow, a PID loop will be the device that does this work. PID stands for Proportional, Integral, Derivative – it is a hardware device that will convert a signal from a flow, temperature, pressure or analyser measurement to an actuator that moves a valve or final control element. The PID algorithm is the software that calculates the speed and behaviour of the actuator such that the process parameter reaches its desired, or “setpoint” value, optimally. The PID algorithm can be tuned for optimal performance, this will maintain all process parameters such as temperatures, pressure, flows etc. at their desired values, thus maintaining process stability.

Often, the responsibility of maintaining PID loops is not clearly assigned to a dedicated group and may fall vaguely between plant operations and instrumentation groups. The task of maintaining PID loops is often seen as a one-off activity that perhaps took place when the plant was commissioned. This is however, far from what should happen. Maintaining PID loops at peak performance is an important task and should be assigned dedicated resources, preferably process control engineers.

What are the best practices that control engineers should use to maintain PID loops at their optimal performance?

Best practices for optimal PID loop performance

Before any work can be done, management at operating facilities need to assign the responsibility of PID loop performance to a group. The group best placed to do this work is process control engineers since they have the correct skills to conduct PID tuning.

A combination of software and good engineering is required to maintain PID loops at optimal performance. PID loop monitoring and PID loop tuning technologies are tools for control engineers to identify and correct PID tuning problems. As always, any software should be combined with best practices to keep PID loops in good working order. Firstly, a methodology should be put in place to identify problematic PID loops. If you have PID monitoring technology, it should be setup correctly so there is confidence in the output and all stakeholders believe the results. Poor performing PID loops should be identified and validated with operations and instrumentation departments, this is to rule out measurement or instrumentation issues. Tuning is the second step and can be done with PID tuning software, using a structured PID tuning approach. Simple PID loops could be tuned based on experience. The third ingredient of maintaining PID loops at optimal performance is a regular maintenance and reporting schedule. Regular 3-month checks should be introduced to reduce problematic PID loops. Simple monthly reports can be generated, showing the number of problematic loops, tuned loops, and outstanding issues. Management should give this activity high priority and should allow sufficient resources for this task.

Well maintained PID loops result in stable process performance

Well tuned PID loops are an excellent example of an activity that requires relatively low effort with potentially significant process benefits. These benefits are in the form of more stable operation, lower product giveaway and better performing Advanced Process Control (APC) applications.

Regular maintenance and performance reporting for PID loops creates awareness amongst all stakeholders such as operations, process and instrumentation departments. This awareness creates focus to resolve outstanding issues such as instrument problems. The overall result of this maintenance and awareness effort is optimally tuned and well-performing PID loops that will improve process performance and possibly reduce wear on final control elements such as valves and actuators.